How to Find Suppliers for Amazon FBA A Founder's Playbook

Finding the right supplier for your Amazon FBA business is a multi-step process. It starts with a detailed product plan and a clear understanding of your costs, long before you even think about searching B2B marketplaces like Alibaba or walking the floor of a trade show. The real secret is doing the prep work first to ensure you find a partner who is both reliable and profitable.

Building Your Sourcing Foundation

Before you even open a new tab for Alibaba or book a flight to a trade show, you need a rock-solid plan. This is a classic rookie mistake: sellers get excited and jump straight into supplier chats without knowing their numbers, only to waste weeks on dead ends.

This foundational stage is where you build a profitable Amazon business. Nailing this part means you can filter out unsuitable factories in minutes, negotiate from a position of strength, and find a true manufacturing partner, not just an order-taker. The goal is to create a detailed roadmap that leaves nothing to chance. This isn't just theory; it’s the practical, nitty-gritty work that separates the seven-figure sellers from those who are constantly battling thin margins and quality nightmares.

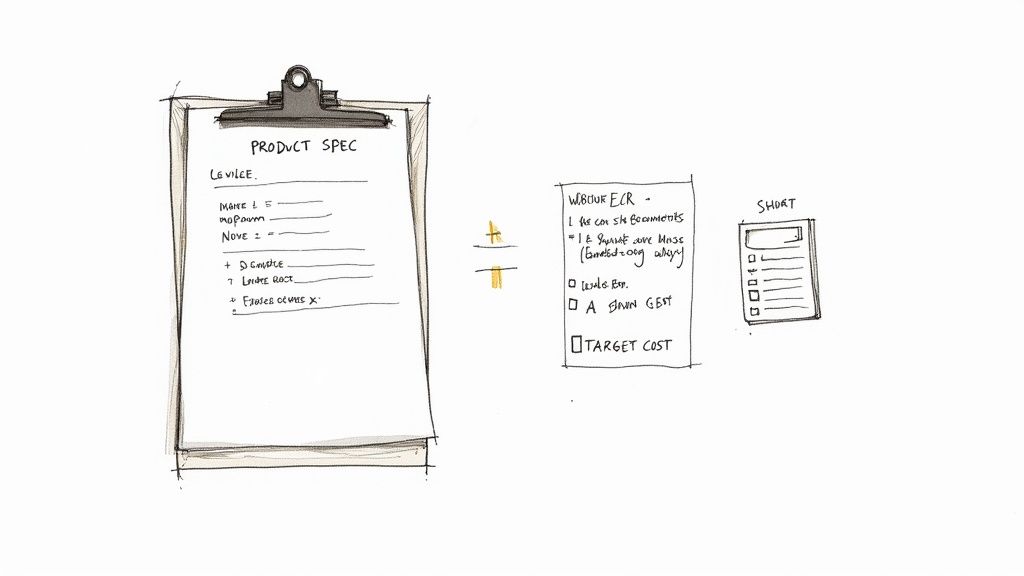

Create a Detailed Product Specification Sheet

Your first mission is to create a Product Specification Sheet, or "spec sheet" for short. Think of this document as your product’s blueprint. It tells a potential manufacturer absolutely everything they need to know, from materials and dimensions to exact colors and packaging requirements.

If you send out a vague request like "I want a silicone baby bib," you're going to get a flood of generic quotes and, frankly, terrible samples. A detailed spec sheet forces every factory to quote you on the exact same product, which is the only way you can make a true apples-to-apples comparison.

A good spec sheet must include:

- Materials: Be painfully specific. Don't just say "silicone"; say "100% food-grade, BPA-free silicone."

- Dimensions & Weight: Give them precise measurements for the product itself and its packaging.

- Color Codes: Never leave color up to interpretation. Use universal codes like Pantone (e.g., PANTONE 18-1663 "Fiesta") to guarantee a perfect match.

- Packaging Details: Detail the box type, any inserts, all required warning labels, and exactly where the FNSKU barcode needs to go.

- Quality Standards: List any certifications you need to sell legally, like ASTM or CE.

Calculate Your Target Landed Cost

There's one number that matters more than almost any other in this business: your landed cost. This is the total, all-in price per unit to get your product from the factory floor, across the ocean, and checked into an Amazon fulfillment center. If you don't know this number cold, you have no way of knowing if a supplier's quote is good, bad, or disastrous.

Your target landed cost is your North Star. It dictates which suppliers you can afford to work with and ensures your product is profitable before you ever place an order.

To figure this out, you have to look way beyond the factory's unit price. You need to estimate several other key costs:

- Shipping Costs: Get some ballpark quotes for sea or air freight from your target manufacturing region.

- Import Duties & Tariffs: Use an online calculator with your product's HS code to estimate the taxes you'll owe.

- Amazon FBA Fees: You have to account for Amazon's referral fees, fulfillment fees, and monthly storage costs.

- Inspection Fees: Always budget for a third-party quality control inspection before your shipment leaves the factory.

Once you add all this up, you'll know the absolute maximum price you can afford to pay the factory while still hitting your desired profit margin. This single piece of information transforms your sourcing from a guessing game into a data-driven strategy.

Discovering Your Ideal FBA Suppliers

Alright, with your business ducks in a row, it's time to get into the fun part: actually finding a partner who can bring your product to life. This is where your idea starts to feel real. The trick isn't just knowing where to look, but understanding how to sift through the noise to find a genuinely great supplier.

Most sellers start their journey on the big B2B marketplaces, but the savviest ones know that a competitive edge often comes from exploring the less-traveled roads. Your first goal is simple: build a solid list of potential suppliers. This gives you options, which is your best form of leverage when it's time to talk specifics and negotiate.

Navigating Online B2B Marketplaces

For anyone new to the game, online marketplaces are the most logical place to start. Platforms like Alibaba, Global Sources, and Made-in-China are industry giants for a good reason—they connect millions of us with manufacturers, mostly from Asia.

The sheer number of listings can be dizzying at first, but these sites have excellent filtering tools. Don't just type in your product and scroll. You need to use the filters to weed out the noise.

Here are the non-negotiable filters I always apply from the get-go:

- Verified Supplier: This is a must. It means a third-party company has done some basic legwork to confirm the supplier's business profile, production capabilities, and quality control processes.

- Trade Assurance: Think of this as Alibaba's escrow service. It protects your payment all the way through to delivery. If a supplier doesn't offer it, I walk away. Period.

- Years in Business: I look for suppliers with at least 3-5 years of experience. New factories can be fantastic, but an established company usually has its systems dialed in and a better track record.

This structured approach is crucial in the hyper-competitive Amazon world. With nearly 2.5 million active sellers globally, finding a reliable partner quickly is key. Vetted directories like Alibaba and ThomasNet are the standard starting point because they offer thousands of options and essential verification details. For more stats on the seller landscape, you can check out this data from Forceget.

Digging Deeper on Supplier Profiles

Once you've narrowed down your initial search, it’s time to put on your detective hat. A supplier’s profile page is a goldmine of information if you know how to read it. Look past the slick product photos and dig into the real details.

First, check out their main products. Do they specialize in your niche, or are they a jack-of-all-trades factory making everything from kitchen gadgets to car parts? A specialized factory will almost always have better equipment, deeper expertise, and stronger relationships with raw material suppliers for your product.

Next, find their business type. Are they a "Manufacturer" or a "Trading Company"?

- A manufacturer is the factory itself. You're dealing directly with the source, which can mean better pricing and more control over the production line.

- A trading company is a middleman. They don't produce anything but have relationships with multiple factories. They can offer more product variety and sometimes lower MOQs, but you'll pay a bit of a markup.

Neither is inherently "bad"—both can be great partners depending on your needs. But you absolutely need to know who you're talking to from the start.

Don't be fooled by professional product photography. The real story is in the details of a supplier's profile: their business type, certifications, and reported production capabilities. That's the stuff that tells you who they really are.

Looking Beyond the Obvious Sourcing Channels

Choosing the right channel to find your supplier can be just as important as the supplier you choose. While the big online marketplaces are a great starting point, different sourcing methods have unique strengths and weaknesses.

Supplier Sourcing Channel Comparison

| Sourcing Channel | Best For | Pros | Cons |

|---|---|---|---|

| B2B Marketplaces | New sellers, product validation, wide selection | Huge variety of suppliers, built-in verification & payment protection, easy to compare options. | Highly competitive, communication can be slow, potential for low-quality suppliers. |

| Domestic Directories | Brands valuing quality, speed-to-market, or "Made in the USA/Europe" claims. | Faster shipping, easier communication, higher quality standards, no import complexities. | Significantly higher unit costs, less product variety. |

| Trade Shows | Serious sellers looking for long-term partners and unique products. | Meet suppliers face-to-face, inspect product quality firsthand, build strong relationships. | Expensive (travel & time), can be overwhelming. |

| Professional Networking | Sellers with industry experience trying to find exclusive partners. | Direct access to decision-makers, less competition, potential for unique collaborations. | Time-consuming, requires a professional approach, lower response rate. |

Ultimately, the best approach is often a blended one. Start broad on a marketplace, then get specific by exploring other channels to find a partner that gives you a true competitive advantage.

Exploring Alternative Avenues

While Alibaba is a fantastic resource, remember that everyone else is using it too. If you're fishing in the same pond as thousands of other sellers, you're all competing for the same fish. To find a true gem, you have to cast a wider net.

Domestic Supplier Directories Check out platforms like ThomasNet in the U.S. or Europages in Europe. Yes, prices will almost always be higher than overseas options, but the benefits can be massive:

- Drastically faster shipping times and lower freight costs.

- No language barriers or late-night calls to match time zones.

- Often superior manufacturing quality and stricter labor standards.

- Zero headaches with import duties or customs clearance.

If your brand is built on quality or a "Made in the USA" promise, or if getting to market fast is your top priority, sourcing domestically is a powerful strategy.

Trade Shows and Virtual Fairs There's still nothing that beats meeting a potential partner face-to-face. Trade shows like the Canton Fair in China are legendary for a reason—they allow you to touch the products, see the quality, and build real rapport. In today's world, many of these major shows also offer virtual fairs, letting you connect with new suppliers right from your computer.

Professional Networking Platforms Finally, don't sleep on LinkedIn. It’s more than just a place for job seekers. You can search for factory owners or export managers in your specific industry and location. A well-written, professional message can cut through the noise of a generic sales inbox and get you a direct line to a decision-maker. It’s an unconventional approach, but it can give you a massive leg up on the competition.

Vetting Suppliers to Avoid Costly Mistakes

Once you've built a solid list of potential partners, the real work begins. Let's be clear: a slick profile on a B2B marketplace is just an advertisement. It proves nothing about their ability to deliver a quality product on time. This is the vetting stage, and frankly, it’s the most critical part of learning how to find suppliers for Amazon FBA.

Cutting corners here is a recipe for disaster. I’ve seen sellers end up with entire shipments of defective products, get ghosted after paying a deposit, or face crippling production delays. Think of rigorous vetting as your insurance policy against these expensive, business-killing mistakes. It’s how you find a legitimate, capable, and reliable manufacturing partner.

First Impressions: Assessing Communication and Professionalism

Your very first interactions with a potential supplier can tell you almost everything you need to know. Treat it like a first date for your business—you're looking for green flags that point toward a healthy, long-term partnership.

Pay close attention to how they communicate. Are their responses prompt, clear, and professional? Or are you waiting days for a short, unhelpful reply? A supplier who’s slow to respond when trying to win your business will be even slower once they have your money.

You’re looking for a sales rep who actually knows their stuff and is happy to answer detailed questions. If they start dodging inquiries about their factory, materials, or production capabilities, that’s a massive red flag. A great partner will be an open book, eager to give you the information you need to feel confident moving forward.

The Essential Document Checklist: Get the Proof

Talk is cheap. Documents provide proof. To separate the true professionals from the pretenders, you need to request specific documentation that verifies they are who they say they are. Don't be shy about this; any reputable factory will have these files ready to go.

Here's what you should ask for:

- Business License: This is non-negotiable. It’s the basic proof that they are a legally registered company in their country.

- Product Certifications: Depending on your product, you might need specific certs like CE (for Europe), ASTM (for toys in the US), or FDA (for food-contact items). Ask if they have existing certificates for similar products they've made. This shows experience.

- Factory Audit Reports: Many larger factories undergo third-party audits (like BSCI or Sedex) that evaluate their quality management systems, ethical standards, and working conditions. While not every factory has one, a recent audit report is a fantastic sign of a well-run operation.

If a supplier hesitates or refuses to provide a business license or relevant certifications, walk away. It's an immediate deal-breaker. Legitimate businesses are proud of their credentials and will share them without any fuss.

The Litmus Test: Ordering and Scrutinizing Samples

No amount of conversation or paperwork can replace holding a physical product in your hands. Ordering samples is an absolute must. It’s the only real way to judge a factory's quality, materials, and attention to detail.

Never, ever place a bulk order without first evaluating a sample. I always recommend ordering from your top 3-5 potential suppliers at the same time. This lets you directly compare their work side-by-side—the quality, the packaging, and even the small details that separate a great product from a mediocre one.

When the samples arrive, put on your most critical inspector hat:

- Material Quality: Is it what you asked for? Does it feel cheap or solid?

- Workmanship: Look for defects, scratches, sloppy glue, or poor stitching.

- Functionality: Does the product work exactly as it's supposed to? Test it thoroughly.

- Packaging: Is it durable enough to survive international shipping? Does it look presentable?

This is also your chance to provide constructive feedback. A good supplier will be receptive to minor tweaks and will see it as a collaborative process. A defensive or dismissive response is a clear warning sign to back away.

Spotting the Trouble Before It Starts: Common Red Flags

Throughout this entire process, you have to stay vigilant for warning signs that a supplier might be unreliable or, in the worst-case scenario, a scam. Always trust your gut—if something feels off, it probably is.

Keep an eye out for these all-too-common red flags:

- Unusual Payment Requests: The industry standard is a 30% deposit to start production and the remaining 70% after it's complete (ideally, after a successful pre-shipment inspection). If a supplier demands 100% upfront or asks you to send money via untraceable methods like Western Union, run. Always use a protected payment method like Alibaba Trade Assurance or a wire transfer to a corporate bank account.

- Vague Timelines and Excuses: A professional supplier can give you a clear production lead time, like "30-45 days after the deposit is received." If they’re evasive and give you vague answers like "soon," it suggests they don't have their production scheduling under control.

- Inconsistent Communication: Are you talking to multiple people from the same company and getting conflicting information? This points to serious disorganization. You need a single, reliable point of contact who is responsible for your account.

By combining sharp analysis of their communication, a thorough document check, and a critical evaluation of their samples, you can confidently filter out the bad actors. This is how you find a true manufacturing partner who will become an asset to your Amazon FBA business and the foundation of a successful brand.

Negotiating Terms Like a Seasoned Pro

Your profit margin isn't made when you sell a product; it's made when you buy it. The negotiation process is where the real money is won or lost, and it's where you turn a good supplier relationship into a truly profitable partnership.

The goal isn't to bully a supplier into the lowest possible price. Sure, you might save a few pennies on your first order with hardball tactics, but that approach often backfires. It can lead to resentment, and suddenly your production runs get deprioritized or, even worse, quality starts to slip.

Think of it this way: you want to build a transparent, mutually beneficial partnership. A supplier who feels respected and valued is far more likely to go the extra mile on quality control and stick to your production schedule. For an FBA seller, that kind of reliability is priceless.

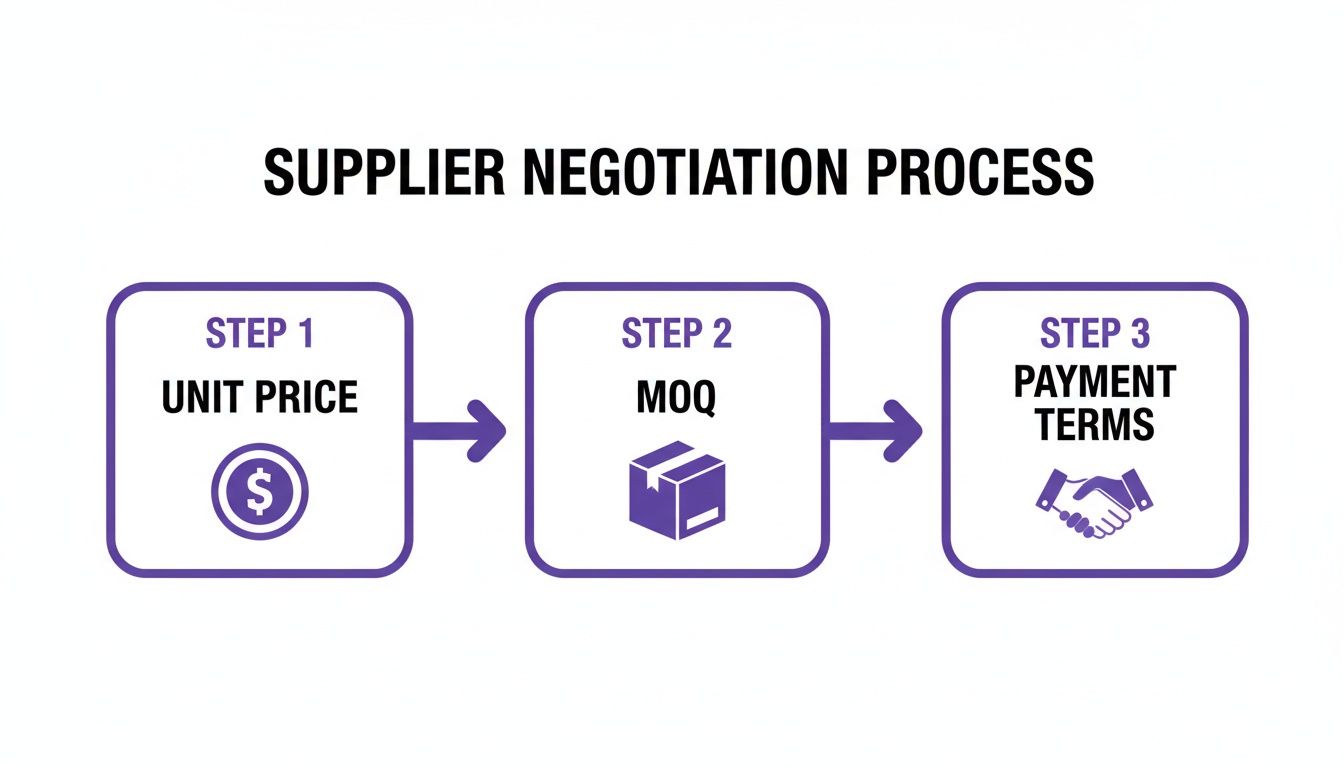

Mastering the Key Negotiation Points

Once you've got a shortlist of potential partners, you need to understand how to negotiate with suppliers on the core terms. Most of these conversations will boil down to three key areas: unit price, Minimum Order Quantity (MOQ), and your payment terms.

You have to go into these conversations with a clear strategy. Know your numbers, know your limits, and be ready to talk specifics.

Unit Price: This is the obvious starting point. While there's usually some wiggle room, don't expect a factory to slash its prices in half. A much smarter move is to ask for tiered pricing. Try asking, "What's the unit price for 500, 1,000, and 2,000 pieces?" This shows them you're planning for growth and gives them a reason to reward you with a better price as you scale.

Minimum Order Quantity (MOQ): For new sellers, a high MOQ can be a killer, tying up way too much cash in inventory. If a supplier's MOQ is higher than you're comfortable with, don't just give up. Ask if they’d consider a smaller trial order, maybe at a slightly higher unit price. Many are willing to be flexible to land a new, long-term customer.

Payment Terms: The industry standard for overseas manufacturing is a 30% deposit to start production and the remaining 70% paid when the goods are finished but before they ship. Never, ever pay 100% upfront. This 30/70 split gives the factory a powerful incentive to get your order done on time and to the quality you expect.

Nailing Down Production and Shipping Details

Beyond those big three, a solid negotiation has to lock down production timelines and shipping logistics. Any ambiguity here is a recipe for disaster and costly delays down the road.

You need to get a firm commitment on the production lead time. A supplier should be able to give you a clear answer like, "Production for 1,000 units will take 35 days from the date we receive the deposit." This is critical for planning your inventory and launch schedule.

Just as important are the shipping Incoterms, which clearly define who is responsible for the goods at every step. You'll most often see two terms:

- EXW (Ex Works): With this, you're responsible for everything—including arranging pickup from the factory floor. It gives you total control but also total responsibility.

- FOB (Free On Board): The supplier handles getting the goods to the port and loaded onto the ship. This is the most common option for FBA sellers and usually offers the best balance of cost and convenience.

Get everything in writing. A verbal agreement on lead times or who pays for shipping isn't good enough. A detailed Purchase Order (PO) protects both you and the supplier and ensures everyone is on the same page.

The Bigger Picture on Sourcing and Margins

While nailing the negotiation is vital, it all happens within the larger world of global trade. For most Amazon FBA sellers, manufacturers in Asia—especially China—are still the go-to source for cost-effective inventory.

By 2025, the vast majority of private-label sellers will still be sourcing from Chinese factories for a simple reason: production costs can be 30–70% lower than Western alternatives for most consumer goods.

That cost advantage is what makes the whole FBA model work, covering Amazon's fees and international shipping while leaving room for profit. Seasoned sellers know this well, typically aiming for a gross margin of at least 30–40% after all costs are factored in. This is a target that's often only possible because of the economies of scale you find in Asian manufacturing. This reality sets the stage for every negotiation you'll have.

Managing Production and Shipping Logistics

Securing a great supplier is a huge milestone, but honestly, that’s just the halfway point. Now the real fun begins: getting your products from the factory floor all the way to an Amazon fulfillment center. This part of the journey is where your attention to detail really pays off—or costs you dearly.

One misstep in production, prep, or shipping can create a domino effect of costly delays, rejected inventory, and a stalled launch. This is the operational side of the business that separates the pros from the amateurs.

Once you’ve vetted your supplier and are ready to move forward, mastering logistics is your next big challenge. It’s all about timing, cost control, and getting the details right. A huge piece of this puzzle is optimizing your international supply chain. Getting a handle on this early will save you massive headaches down the road.

The Non-Negotiable Pre-Shipment Inspection

Let me be crystal clear: do not send the final 70% payment to your supplier until you’ve had a third-party inspection done. This isn't a "nice-to-have" or an optional add-on; it's a critical risk management step that can save your entire business.

For a few hundred dollars, an independent inspector will go to the factory, pull a random sample of your finished goods, and check them against the exact specifications you provided. They are your eyes and ears on the ground.

This inspection is your last line of defense. Imagine the nightmare of discovering a critical flaw in your product after it’s already landed in an Amazon warehouse. An inspection catches these deal-breaking problems while your inventory is still at the factory, making it the supplier's responsibility to fix them.

It’s surprisingly easy to arrange. You give the inspection company your spec sheet and a checklist of what to look for. They handle the factory visit and send you back a detailed report, complete with photos and videos. This report gives you the confidence to approve the shipment and release that final payment.

Communicating Amazon FBA Prep Requirements

Amazon has notoriously strict rules for how products need to be prepped and packaged before they arrive. If you don't follow them to the letter, you risk your shipment being rejected, returned, or hit with unplanned prep fees that silently drain your profits.

Your supplier needs to understand these requirements before production starts. You have to spell it out for them.

- FNSKU Labeling: Every single unit needs an Amazon-generated FNSKU barcode. You'll need to provide the printable label file and be specific about where it needs to be placed on the packaging.

- Suffocation Warnings: Is your product in a poly bag? If that bag has an opening of 5 inches or more, it legally requires a suffocation warning label. Don't forget this.

- Carton Specifications: Amazon has strict limits for shipping cartons. They can't exceed 25 inches on any side or weigh more than 50 lbs, unless a single unit inside is oversized. Make sure your supplier knows these limits.

Before you even get to this stage, your negotiations on price and terms set the foundation for a smooth production run.

Getting unit price, MOQ, and payment terms locked in first allows you to focus entirely on these crucial production and shipping details.

Demystifying International Freight

Getting your inventory from a factory in China to a warehouse in Ohio involves a complex dance of international freight, customs, and import duties. Don't try to manage this yourself at the beginning. You need a freight forwarder.

Think of a freight forwarder as a travel agent for your cargo. They book space on ships or planes, handle the mountain of paperwork, and navigate your shipment through customs. They are worth their weight in gold.

You’ll generally have two choices for shipping:

- Sea Freight: This is your workhorse. It's by far the most cost-effective way to ship in bulk. The trade-off is time; you're looking at a 30-45 day transit time. But for keeping costs low, you can't beat it.

- Air Freight: When speed is everything, you use air freight. It’s significantly more expensive, but your goods can arrive in just 7-10 days. This is perfect for launching quickly or for emergency restocks when you're about to run out of inventory.

Your freight forwarder will also be your guide through customs clearance. They'll make sure your commercial invoice is accurate, classify your products with the right HS code, and handle the payment of all import duties and taxes. Getting this part right is a core skill for any serious FBA seller.

Let's Talk About Sourcing Wholesale

Private label gets a lot of hype, but it's not the only game in town. The wholesale model is a fantastic—and often much quicker—way to build a serious Amazon FBA business. Instead of creating a product from the ground up, you simply buy existing, well-known brand products in bulk and resell them on Amazon.

Think about it: you're not trying to convince people to buy something they've never heard of. You're tapping into a market that's already there. Customers are actively searching for these brands, meaning you can get sales rolling almost right away without a huge marketing budget. It's a business model built on leveraging established brands and moving fast.

Why Go the Wholesale Route?

Sellers love wholesale for a few key reasons, especially those looking to diversify or just get to market without the long wait. The perks are a world away from the slow, drawn-out development cycle of a private label product.

Here’s what makes it so appealing:

- Built-in Demand: You’re selling products that already have a solid sales history and brand recognition. This drastically cuts the risk of sinking money into inventory that just sits on a shelf.

- Lightning-Fast Launches: The time from finding a product to making your first sale can be just a few weeks. Compare that to the many months it takes to design, manufacture, and ship a private label item from overseas.

- Smaller Minimum Orders: Distributors typically have much lower Minimum Order Quantities (MOQs) than factories. This lets you test the waters with new products without tying up thousands of dollars in a single SKU.

How to Find and Land Wholesale Accounts

So, where do you find these wholesale suppliers? It's a different hunt than scrolling through Alibaba. Here, your goal is to connect with domestic distributors or the brands themselves. A great starting point is to pick a product you're interested in, then reverse-engineer the supply chain by searching online or contacting the brand directly to find their official distributors.

When you make that first call or send that email, you need to look professional. Have your registered business entity and reseller’s permit ready to go—they won't take you seriously otherwise. Your first goal is to simply open a wholesale account to get your hands on their product catalog and pricing. Don't be surprised by how common this is; marketplace stats show that somewhere between one-quarter and one-third of sellers are using wholesale to scale. You can discover more insights about these marketplace trends and see why it’s so popular for building cash flow with high-velocity items.

Heads up: The single most important part of wholesaling is getting brand authorization. If you resell branded goods without clear, written permission, you’re asking for an intellectual property (IP) complaint. That's one of the fastest ways to get your Amazon account suspended. Always, always get it in writing.

Before you pull the trigger on an order, you have to do your homework. Use a tool like Keepa to dig into a product's sales rank history, price fluctuations, and how many other sellers are on the listing. This data is non-negotiable—it tells you whether a product actually has enough demand and profit margin to be worth your time. For anyone looking for a scalable, faster path to revenue, wholesale is a strategy you can't afford to ignore.

Ready to slash your software costs and find winning products faster? EcomEfficiency bundles over 50 premium e-commerce tools for product research, SEO, and advertising into one simple subscription. Unlock tools like Helium10, Semrush, and Midjourney for as little as $19.99/mo and save up to 99% on your monthly tool spend. https://ecomefficiency.com